Mining Applications

Utilizing drones in the mining industry is demonstrating exceptional results with greater data collection, enhancing safety and improving productivity.

Using Survey grade Cameras, Lidar and Thermal cameras on our drones, we are able to assit you in your requirements and inspections.

Spontaneous Combustion

In coal mines, drones can be used to detect hot spots in coal stockpiles to assess potential spontaneous combustion areas and enable personnel take preemptive measures.

Automatic surveying and mapping

Surveying and mapping of mining areas is a time-consuming process. By untilising drones instead of a piloted plane a mine can save hourly costs, collect aerial data, apply measurements and capture high end DSM’s, DEM’s, contours, orthophotos and more.

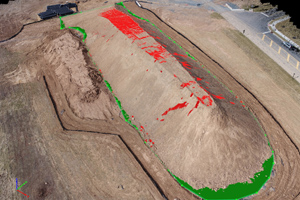

Stockpile management

Height and area are one of the greatest challenges mining companies face while managing stockpiles and the frequent changes that occur. Mining companies can monitor inventory using drones to generate aerial terrain models.

Effective management of stockpiles could yield significant benefits for mining companies such as grade maximisation by blending of ore, production backup during situation of supply disruptions, and financial reporting.

Mines require volumetrics to be done on their stock piles and to ascertain that they are correct in their calculations as well as to monitor their assets.

Site safety management

Application of drones for collecting visual data particularly of difficult and volatile areas such as deep and high terrains of a mine, highwalls, crests, and inside stopes. Further, aerial data capturing from blast sites, reduces the risk of exposure on the ground to such dangers.

Security

Drones are being used to look at perimeters and conduct constant surveillance over large areas. Drones can also be sent out as a response mechanism before personnel can respond and conduct an initial site assessment, so people know what they’re getting into before they get there

Tailings dam management

Utilisation of drones to measure tailings dams could eliminate the risk of manual surveying. There is no need for manual interference within the proximity of the dump when drones are around. By analysing the captured data on a digital platform, mining companies can maintain structural integrity of the tailings dam, design expansion and avoid failure.

There are a few common causes for dam failures:

- Seepage and leaking pipes

- Maintenance and poor management

- Unreliable manned data which is generally inaccurate

Drones offer a fast, safe, easy and inexpensive way to assist in prevention of dam failures.

Monitoring and inspection

Mining is one of the most unsafe industries for workers, especially when performing deep underground activities. Rock falls, humid conditions, gas leaks, dust explosions or floods, amongst other hazards can have an impact on staff. Mining companies are therefrore using drones underground, to monitor and inspect deep underground shafts.

Drones are also being used for inspection of mining equipment, which is expensive and time-consuming and requires highly skilled labour.

Haulage road optimisation

The haul road network has an impact on the efficiency of mining activities. For safety and uniformity, the haul road conditions must be continusoulsy monitored. Drones can be used to collect a large amounts of aerial data, covering wider areas precisely, which can then be used by engineers for planning, designing, construction and maintenance of haul roads.